Water Hand Pump Repair Requires Training and Experience, But There Are Some General Guidelines That Pertain to Any Pump Repair Endeavor

WATER HAND PUMP REPAIR GENERAL GUIDELINES

Note: Much of the content on this page has been adapted from publications of Lifewater International, written by Fred Proby.

Even though hand piston pumps are not terribly complicated mechanisms, water hand pump repair is a technical and sometimes physically demanding operation.

It requires experience and training. Hands-on training by qualified and experienced trainers is by far the best way to learn the basics of hand pump repair.

The process is so physical and so “hands-on” that it is impossible to cover it adequately on this website.

Piston pumps work by similar principals, but the parts and engineering approaches used to solve similar problems may be very different.

The information written here is of a very general nature. Use it as a guide, and be sure to get instruction pertaining to your specific hand pump and its repair before you dive into a repair job.

Safety is the main concern.

Safety should always be first on your mind. Much of the goal of training in water hand pump repair is learning how to accomplish a repair safely.

Pulling pump rods and riser main sections out of the ground means that you will have heavy metal hanging over your head (wear hard hats).

Also, it is easy to let heavy parts fall back into the well which can injure hands and fingers.

You may well be required to troubleshoot problems on a pump cylinder that is hundreds of feet below ground.

Safely getting the pump out and repaired requires teamwork, knowledge of water hand pump construction and disassembly processes, and great care in not contaminating a perfectly good well.

There are some non-profits that offer training in hand pump repair.

Seek out valuable hands-on training programs before you set out to repair the world’s pumps!

Even with training, experience is always the best teacher. Manuals are available for most water hand pump types, and some of these are available on this website as PDF files that you can download.

Even so, do not attempt to repair any pump with which you are not completely familiar.

There are a few items to remember as a general approach to repairing hand pumps.

Water hand pump repair should always begin with a plan. It would be a mistake to dive into a repair job without preparing properly to undertake the task.

Following are a few things you must consider before you start any repair operation.

* Ask PERMISSION to Work on the Well

As always, it is important to be sure to include the community in every aspect of a water project including repair of a broken water hand pump.

After all, this may be the only well they have, and you will be taking it out of commission.

Even if it is not functioning at the moment, pulling the pump out of the well may cause the community some concern.

There may be good reasons, unknown to those repairing the well, that the well is not working.

The community knows the history of the well and the pump, and is a vital source of information. The community needs to know that the pump is being worked on, what is being done to it, and why it is not in the well.

* Find Out If There Is WATER IN THE WELL

Maybe there is nothing wrong with the pump. Maybe the well is dry or, if it is the dry season, maybe the water level has fallen below the intake of the water hand pump cylinder.

Again, the people in the community can tell you if there are times of the year that water does come out of the well.

* Be Sure That You KNOW HOW to Work On the Specific Water Hand Pump in Question

If you are not familiar with the type of water hand pump you want to repair, there is a good chance that you should not even get into it.

Don’t try “experimenting” as a troubleshooting technique. If you do not have a manual for, say, a proprietary pump that you have never seen before nor opened up before, you could easily make a bad situation worse.

Experience is the best teacher. The more experience you have as a water hand pump repair technician, the more likely it is that you will be able to handle the repair of an unfamiliar pump.

* Do You Have All the PARTS AND TOOLS Needed to Fix the Pump?

You cannot fix a water hand pump if you don’t have the necessary tools. Likewise, you cannot fix a pump if you don’t have the needed parts. You want to be sure that you have everything you need to repair it.

You wouldn’t want to get started on a repair job with the community’s expectations high and then have to abandon the project because you were not prepared.

Be sure to have the tools and parts on hand before you begin any repair job.

TEN PROCEDURAL STEPS TO EFFECTIVE HAND PUMP REPAIR

Getting ready to do a repair job correctly means giving the whole job careful consideration, from its beginning to its end.

It means thinking through the whole process before you ever lay a wrench on the pump. It also means having a systematic approach; taking things one step at a time.

The following are general procedural steps for completing any water hand pump repair.

Since community involvement is THE MOST important aspect, it is always the first step. Always work closely with the people who are responsible for the well.

1. Look at the outside of the water hand pump. Look at the above ground parts to see if there are any obvious clues to its condition.

Looking at the above-ground parts of a water hand pump may help determine the problem. Look for obvious things, like a missing pump handle, a broken pump head, or signs that the pump has been neglected and unused for a long time.

If a pump handle is worn and shiny, this may indicate that the water hand pump is used frequently. Check to see if the base is broken or cracked and if the pump head is loose.

Check to see if there are weeds growing in the run-off channel and soak-away pit? This may indicate that water is running through them as it should. Is there a path worn to the pump where people walk frequently?

If there are iron stains on the concrete pad, this can indicate that there is rust in the pump parts. If there is sand present just under the spout, this may be an indication that the well is “pumping sand”.

There may be a problem below ground that is allowing sediment to enter the pump cylinder and be pumped out with the water. Sediment in the pump cylinder will wear out the pump seals.

What is the condition of the pump pad? Is it cracked? Has the ground around the pad eroded? Such erosion can allow contaminated surface water to seep into the well. Has the pump pad been repaired in the past?

Does someone come to talk to you when they see you looking at the water hand pump? This is a good sign, since it indicates that people feel a sense of ownership of the well.

2. Talk to the community about their water hand pump.

You would want to ask who is in charge of the well and the water hand pump. Ask if there is a Water Committee.

Find out the story behind the pump. Does the village value the well and use it frequently when it is working?

Do they feel that it is “their well”? This is important and it is common that outsiders may come and install a well and pump and never really hand over ownership to the community.

The villagers can easily feel as though it belongs to someone else and not to the community.

Do the people of the community like the water that comes from the well? Does it taste good to them? Does it have a pleasing taste or any objectionable odor or color?

There may be cultural biases or myths that prevent villagers from using the well.

The location of the well (possibly near ancient burial grounds) or the positioning of the well (like facing east toward Mecca, for example) may be legitimate cultural reasons for a well not being utilized by community members.

Also, having a well that is conveniently located is important. If it is too far away, people will just not use it. They will tend to go to the easier watering spot, even if the water is unsafe to drink.

It may be important to know who installed the well and when. It may be that the people who installed it did not speak the local language and did not provide any guidance as to pump maintenance or repair.

Again, the villagers may feel that this is “their” well and not “ours”.

Try to find out how deep the well is, how much water is in the well, flow rates during certain times of the year, and how far down the pump cylinder is.

Ask if there are any repair records. Have the piston seals ever been replaced and when? When was the last time the water hand pump actually worked correctly?

There may be someone in the village who is trained to repair the water hand pump. Find out about the availability of spare parts.

3. Test the water hand pump

You will want to be sure that you can operate the pump handle and pump rod in order to test the pump.

So, when you inspect the above-ground parts of the water hand pump, take a good look at the pump handle bearings, any connecting chains (connecting the pump handle to the pump rod) and bolts that hold these moving parts together.

Be sure that the water hand pump is securely attached to the base and that all nuts and bolts are in place.

Try operating the pump rod. Look, listen, and feel how the pumping feels. Is the movement of all parts smooth or is it clunky, grinding, or loose? Is there any sideways play in the pump handle?

Does the pump handle feel unusually heavy or light? Is there enough weight of water in the riser main to pull connecting chains tight?

If water comes out of the well, is it clear or is there sediment in it?

Listen for anything that does not sound right. If you hear water leaking, if the pump sounds rough or broken, if the connecting rods are scraping or loose; hearing these sounds and identifying them helps to troubleshoot the problem.

4. Before any repair begins, conduct a simple pump test and leak test

Pump Test and Leak Test Procedure

Pump Test

1. Operate the pump until water comes out the spout

2. Place a bucket under the spout and then pump 40 full strokes

3. Measure the volume of water pumped

[Alternative: Count the number of strokes needed to produce 20 liters (5 gallons)].

Leak Test

1. After the pump test, let the pump remain idle for 5 minutes.

2. Pump again and count the number of strokes needed before water comes out again.

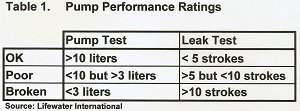

Table 1 indicates how a pump would perform if it were performing okay, performing poorly, or if it was broken.

5. Check to be sure that there is water in the well

Try to determine the water level in the well and if the pump cylinder is below the water level.

Loosen the pump from the base and slide it sideways so you can see down the well along the outside of the riser main. Use a flashlight or reflect sunlight down the well to see if you can see the water level.

Also, you can use a weighted string or measuring tape to put down the well and find the water level.

6. Disassemble the hand pump

Before you disassemble any pump, be absolutely sure that you understand what is most likely wrong with the pump.

Be sure that it is really necessary to disassemble the pump. Disassembly is potentially one of the most time consuming, and dangerous parts of pump repair.

Don’t enter into this exercise unless you are positively sure that it is necessary to get the pump working.

Discuss the repair with the community members and inform them of what is most likely wrong and what it will cost to repair the pump. If they agree then proceed to disassemble the pump and verify what you think is the problem.

If you are working with an open-top cylinder, you may not have to remove the riser main.

If you are working with a closed-top cylinder, then it will be necessary to take precautions since riser main pipe comes in heavy, long sections.

You may have to use a tripod and block and tackle to lift it out of the well a little at a time.

Keep careful track of pump parts and tools. Put bolts and nuts in a secure place where they won’t get misplaced.

It is best to have a tarp or some kind of clean surface to lay tools when they are not in use. Keep them away from the pump so they don’t become a trip hazard for the workers.

There will usually be a crowd of curious onlookers watching your work. It is important to set up a perimeter with rope to keep visitors at a safe distance and to keep the workers and pump parts and tools safe and secure.

There are two things that you must be attentive to when working when pulling pumps out of a well.

Safety is number one. Workers should all have hard hats on since there is a lot of steel overhead and things to bash you head on around the work site.

Workers should also have gloves since they are handling steel that can have rough, sharp edges. Also, there are many opportunities to get your skin, finger, or hand pinched between pump parts.

Parts and tools can be heavy, so wear boots to protect your feet.

The other risk that is always present when pulling a pump from a well is the possibility of losing things back down the well.

This can happen when disconnecting riser main sections. Riser mains should always be clamped so that they do not fall down the well.

Also, pump rods need to always have a “T” handle attached to the top to keep it from falling into the well. Remember that the pump rod is connected to the pump cylinder.

If there is a loose joint between riser main sections that you are unaware of, the riser main could separate and the bottom part will fall down the well, trying to take the pump rod with it.

Be observant as you bring the riser main out of the well. If the riser is bent or has a hole in it somewhere, you do not want to miss that important fact.

If the riser main suddenly appears to be wet on the outside, this could be where the riser enters the water level or it could also be a leak in the riser main.

If it is the water level, then measurement of the length of riser main you have removed should match the measurement you took before of the water level in the well.

Check each riser main connection to be sure that it is holding water and not leaking. Also, look for any holes in the riser main.

As you remove riser main sections from the well, set them on pieces of wood, off the surface of the ground, and in the order in which you took them out.

Keep track of how many sections of pipe have been removed and the depth measurement of any anomaly you might come across. These observations and measurements can help in troubleshooting or preventing future problems.

Once you have removed all the riser main, pump rod, and pump cylinder, look down the well (again, using a flashlight, mirror, or reflected sunlight).

Measure the well diameter and note the material it is made of. Check for any irregularities in the well casing such as obstructions, broken casing, or sediment.

All of this should be entered in a Pump Repair Record for future reference.

Pump cylinders are often the below-ground part of the pump that breaks or malfunctions. All the moving parts, pressures and tolerances of the pump cylinder, often (but not always) make it a prime suspect in pump malfunctions.

Check the outside of the pump cylinder for corrosion or cracks. Open up the cylinder and check the condition of the piston seals, travelling valve, and foot valve.

These often fail, break, or just wear out. Inspect the inside of the cylinder barrel to be sure it is straight and smooth and not worn or uneven.

By this point, you may have been able to ascertain the problem with the pump. Hopefully you will have some spare parts with you, like spare seals, piston seals, traveling valves, foot valves, spare sections of pump rod and riser main, and various nuts and bolts used on the pump.

Discuss any problems you find with the community members and discuss what it will cost to make the needed repairs.

If you don’t have the right spare parts with you, you may have to find someone who has what you need and bargain, buy, or trade for them.

If this is going to take some time, or if the community needs time to raise the money for the parts, then it is best that you reassemble the pump.

Doing this will seal up the well again, keeping it safe from contamination, and it will help keep all the parts of the pump together and secure.

Be sure to emphasize that this pump belongs to the community and it is their responsibility to take care of it and get it repaired.

7. Make the repairs

Once you have obtained the parts you need to repair the pump, if you needed to put it back together to wait for parts, you will have to pull the pump out again.

It seems like a lot of extra work, but lots of things can happen to parts, tools, and a well site, if the pump parts are left unassembled and the well left unsecured.

Train others to work on the pump. This is a very important part of creating sustainability of a community water supply.

Train at least two community members how to pull, repair, and replace the hand pump and give them your contact information so they can contact you if they need advice.

Also give them contact information about or show them where to get spare parts.

Once you have gone through the process of pulling all that riser main, the pump rod, and the pump piston, it is best to consider your endeavor as pump “SERVICING” and not just pump “REPAIR”.

There are many parts that can easily be replaced, since you already have everything out of the ground. You might as well replace and service the entire pump. This precautionary measure may easily prevent future malfunctions.

Here are some things you can do that will help assure long-time excellent water hand pump performance. You should do these things even if these parts are not broken or worn.

Change the piston seals even if they are not badly worn.

Ensure a full piston stroke. That is, ensure that the piston clears the cylinder top and bottom during each stroke.

Check the pump handle weight. The pump handle may too light for the size of the column of water you are trying to lift. You can add an extension to the pump handle or add counter weights to the handle to make pumping easier.

Make sure all the nuts and bolts are tight.

Repair the cement pump pad as needed.

Discuss fencing off the hand water pump and well area if needed.

A fence is a good way to protect this important water source.

Examine, and if needed, improve the grade of the slope around the pump pad to assist in proper drainage away from the well and pump.

Clean out the drainage ditch and soak pits as needed.

Chlorinate the well. Be sure that you are leaving them with a well that is pumping clean safe water. Water hand pump repair processes can introduce contaminants to the well (for instance, if a riser main section touches soil and is then inserted back into the well).

Take water quality samples. This is good to do, and is a requirement in some countries.

8. Replace the water hand pump in the borehole

Before you put the repaired pump cylinder back in the well, test it first.

Test it more than once, since you don’t want to go through the repair process again if you get the pump cylinder to the bottom of the well and it still doesn’t work!

Put the pump cylinder in a bucket of water with the pump rod and pump piston pushed all the way to the bottom of the cylinder. Pull up on the pump rod, pulling the cylinder up and drawing water into the pump cylinder.

Lift the cylinder out of the bucket and see if water leaks out. This is a good test of the foot valve to ensure that it holds water in the cylinder.

If it does, use your finger to push the foot valve up and release the water. It should drain out the bottom.

If you alternately pull and push the pump piston up and down through its stroke, water should be drawn up through the foot valve and out the top of the pump (up-stroke) and the pump piston should be easily returned to the bottom of the stroke (down-stroke) with the upper cylinder filing with water again.

If this process works freely, then it is safe return the pump cylinder down the well.

When setting the depth of the pump cylinder in the well, consider the best pump depth. You might be able to improve a well by setting the pump cylinder deeper or by adding a length of tailpipe, thereby increasing the operational depth of the pump.

This takes experience and knowledge since you must know the static water level of the well, the depth of the well casing, and the seasonal fluctuations of the water level.

Anytime a borehole is exposed, the well must be chlorinated.

Conduct a post-repair pump test just like you did before you began the repair. Compare the two, and if there is no improvement, we have to ask, “Why”? What did we overlook or what did we do wrong?

This could happen the last part of the day with a long drive ahead of you to get back to your bunk.

This, however, is not the time to quit. It is not good enough to say “Well, we tried our best. At least they are better off than they were.” This is the time to dig deep and commit yourself to doing the job right.

Pull the water hand pump out again and re-check everything to find what was overlooked. What if this was your well? The whole community, men, women, and children are counting on you. Like the guy says, “Get ‘er done!”

9. Emphasize and reinforce the community’s ownership of the water hand pump and well

The community will be very happy to see clean safe water coming from a well that has not been working for months or even years. For some of them, it means not having to haul five gallons at a time two or three kilometers every day.

They will want to celebrate!

This is a good time to discuss with the leaders how to encourage the community to appreciate the value of their well as a resource that can help improve community health and well-being, and how important it is to their children and coming generations. Review community plans for pump maintenance and oversight, including the Water Committee.

Discuss ways to minimize maintenance problems.

* Do not allow children to play on the water hand pump (another good reason to fence off the area).

* Use long full strokes when pumping water, not short quick strokes.

* Tell them who to contact if problems develop.

Be sure that everyone knows to wait 24 hours after chlorination to drink the well water.

You may have to lock the pump handle with a padlock and give the key to a community leader. People can get sick if they drink the chlorinated water. After 24 hours, pump the well until you can no longer smell the chlorine.

10. Learn from your experience

Every water hand pump repair project is a new experience. You will learn something new every time.

Was your troubleshooting accurate? Did you overlook anything? If so, what was it and what can you do next time to prevent the same occurrence?

Experience with a variety of hand pumps and a variety of situations will improve your pump repair skills.

Preventive Maintenance

Work with the community to help set up a program of preventive maintenance.

Maintenance should be done on a pump and its surrounding area on a continual basis.

You know the saying:”An ounce of prevention is worth a pound of cure”?

Unfortunately, there is another saying: “Don’t fix something if it’s not broken”.

Preventive maintenance is a must.

Preventive maintenance can ensure that serious breakage, malfunctions, and contamination do not occur and that they are detected and fixed before they force a shut down of the water supply.

The capacity of a village to perform its own preventive maintenance can make the difference between a successful water project and loss of water altogether.

Some of the tasks that need to be addressed and scheduled at regular intervals include the following:

Weekly

• Lubricate moving parts.

• Check and tighten nuts and bolts.

• Make sure the water hand pump is firmly set in the base.

• Keep well pad and area around the well clean and neat.

Monthly

• Check pump flow rate and record results.

• Repair concrete base and apron as needed.

Common Pump Problems

Water hand pump repair technicians will encounter a number of problems. Sometimes they will see the same problem over and over again in the same pump type or in the same geographic area.

There may be more than one thing wrong with a water hand pump. This complicates the situation. Never be satisfied if you find one problem and fix it. Be on the lookout for other problems that might need to be addressed.

Below is a short list of commonly experienced malfunctions and common underlying causes. This is by no means an exhaustive troubleshooting guide.

Some problems arise more often than others for rather predictable reasons, but the unexpected is always just around the corner.

Problem) Low yield (less than 10 liters in 40 strokes)

Underlying Cause) Worn piston seals or lowered water table

Problem) Prematurely worn piston seals

Underlying Cause) Sand or silt in the well

Problem) Needs many strokes to bring up water

Underlying Cause) Leaking foot valve or leaking riser main

Problem) Frequently separated pump rod or chain

Underlying Cause) No lock nuts in place or not joints not adequately tightened

Problem) Broken pump rod

Underlying Cause) Crooked threads or improperly tightened joints

Problem) Contaminated water

Underlying Cause) Well may be too close to a latrine, no sanitary seal, or a broken pump pad.

Read About The Experiences of Others

Click below to see contributions from other visitors to this page...

Hand Pump is pumping sand!

My hand pump froze. Got it thawed, but now it is getting fine sand particals, and will not hold a prime. sometimes it will hold, and other times it won't …

hand pump is not giving water..

hand pump is not giving water, we are trying o pour water into it from the top to build pressure but no result, please advice how to fix.. Thanks..

afridev pump question

my hand pump can not pump water again and the handle tends to Go down with force after lifting. what could be the cause?

Hand Pump has become quite heavy to pump by hand

Dear Sir,

My hand-pump has become very heavy to be pumped. It takes a lot of effort to move the handle and thus very tiring.

water level in well = 120 …

vacuum question

gud day, we have a hand water pump in our house but not connected to deepwell. only 6 stroke to pump water then its hard to pump. i think the problem is …

sideways play in pump handle

Have a hand pump that was installed new in 1999 and used almost daily for water for a few head of livestock. Lately I've noticed sideways play in the …

Campbell pitcher pump question

We have a shallow well that I wanted to use to water our animals with in the winter, when hoses have been put away. The first winter here, our young daughter …

Great How To Not rated yet

Thank you for the post. My friends recently bought some land up in Montana and they are need to do some well pump repair. This is a great how to and I …

antique suction pump Not rated yet

Would like to install Antique Suction Pump.

Electric pump and pump house long gone.some kind of metal fittings located in center of concrete slab. Slab …

village style hand water pump Not rated yet

I have a village style hand pump fixed to a oak water barrel .water goes into barrel via rainwater pipe. this has worked well, but it has now stopped …

Reverse movement of pumps Not rated yet

The hand pump brings water out twice then the handle makes a reverse action so that the handle bumps out , then no water yield is there.But you can see …

Return to "Hand Pumps" From "Water Hand Pumps"

Return "Home"