Well Disinfection and Well Development are Important Measures that Ensure a Safe and Dependable Source of Water

Well disinfection and well development are important measures that ensure a safe and dependable source of water.

Note: Much of the contents on this page has been adapted from publications of Lifewater International, written by Fred Proby.

The final sanitary condition of water taken from a well is probably the most important factor to consider when drilling wells. The goal, after all, is to provide a dependable source of drinking water that is free of sediment and free of disease-causing pathogens.

Therefore, time spent on well development and well disinfection is never time wasted. We should be willing to spend at least the same amount of time on these two steps as we spend on the drilling of the well.

Once a well has been drilled, and the above-ground parts properly constructed. A well must be “developed” and “disinfected”.

Well development is a process of moving water back and forth through the gravel pack and pumping a large amount of water out of a newly drilled well.

The purpose of this process is to remove the drilling mud from the well, break down the “wall cake” that the drilling process creates, and remove sediment from the well water.

It may take a couple of days of continuous pumping to accomplish these goals and completely develop the well.

Well Disinfection

Note: It is very difficult and problematic to disinfect a hand-dug well.

Disinfection of hand-dug wells is more difficult than disinfecting drilled wells. The quality of water taken from hand-dug wells is often very poor, mainly due to the poor construction of the above-ground elements and unhygienic methods of collecting water.

A rope and bucket, for example, may be used to collect water, and the rope and bucket are often left on the ground and exposed to disease-causing pathogens.

There is often no sanitary seal in hand-dug wells, and the construction of the above-ground parts of the well does not provide adequate protection from intrusion of surface water and dirt.

Because of the large diameter of hand-dug wells (one meter or greater), the volume of water in the bottom of a hand-dug well is often greater than that in a drilled well. The larger volume requires a larger amount of chlorine for disinfection.

A hand-dug well may require disinfection every day before being used. At a minimum, the wells need to be disinfected every week or two. Disinfection needs to be performed, not only on the water in the well, but also on the well casing.

In a hand-dug well, this requires scrubbing the walls of the well casing using a brush or broom and a chlorine solution. Buckets and ropes, or whatever methods are used for collecting water from the well, must also be disinfected, or they will contaminate the well when they are used.

Therefore, the information that follows pertains only to drilled wells.

As illustrated in the water well diagram , proper well construction (specifically the sanitary seal and pump pad) assures that the well will be protected from the introduction of surface water and pathogens from above ground.

The well drilling process will easily introduce foreign matter into the well. The water in the well and all the parts of the well, including the well casing and pump, must be disinfected using a chlorine solution.

Three things that must be remembered in regards to well disinfection:

1. The amount of chlorine required depends on the volume of water in the well and the concentration of the chlorine source. Water volume is calculated from well depth, water level, and borehole diameter (well casing plus gravel pack). The concentration recommended for “shock chlorination” is 250 ppm, or 250 milligrams per liter.

2. The chlorine should be mixed thoroughly in the well casing, pumped until you smell chlorine in the outflow, then left in the well casing and inside the pump overnight.

3. The chlorine, must be completely pumped out before people drink from the well.

Chlorine is readily available all over the world. It can be purchased as either liquid bleach of 3.5% or 5% chlorine concentration, or as powdered chlorine of 70% chlorine concentration.

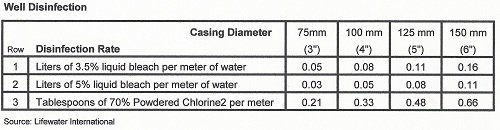

If we know the concentration of the chlorine source we are using, the diameter of the well casing, and the depth of water in the well, we can use the "Disinfection Rate" table below to find the amount of bleach or powdered chlorine needed.

Follow these steps:

1. Determine the depth of water in the well (in meters).

2. Find the row in the Well Disinfection table corresponding to the concentration of your source of chlorine.

3. Read to the right until you come to the column representing the diameter of your well casing.

4. Multiply the number in that cell(the Disinfection Rate) by the meters of water in the well to get the liters of bleach(or teaspoons of powdered chlorine) needed to for well disinfection.

Example:

If the water depth = 15 meters

Your chlorine source = 3.5% bleach

The well casing diameter = 100mm

Disinfection Rate = .08

.08 x 15 meters = 1.2 liters of bleach required

Return to "Groundwater" from "Well Disinfection"

Return "Home"