Types of Hand Water Pumps Include Shallow Well and Deep Well Piston Pumps. Some Pumps Offer Village Level Operation and Maintenance Capability

Types of hand water pumps include piston pumps used for shallow and deep wells.

Some hand water pumps offer village level operation and maintenance capability (VLOM).

Types of Pumps and Hand Pump Operation

Lifting water out of a well always involves overcoming the weight of the water in order to raise the water from some depth to the surface where it can be used, stored, or transported.

Many methods have been devised to accomplish this, from the simple to the complex.

Hand-dug wells, for example, often do this with a simple rope and bucket. Water is physically lifted out of the well. This is an example of “direct lift”.

Other, more sophisticated methods of "direct lift" are provided by propeller pumps, centrifugal pumps, air lift pumps, and siphons.

Our discussion will be limited to hand water pumps classified as“displacement pumps” (or positive displacement pumps).

The majority of pumps used in developing nations are “displacement pumps”.

Because water cannot be compressed, it can be pushed or “displaced”.

The most commonly used displacement pumps are also referred to aspiston pumps because they utilize a piston sealed within a cylinder to displace water upwards out of the well.

Piston pumps fall into two categories, suction pumps and lift pumps(other pumps that take advantage of this principle include progressive cavity pumps and diaphragm pumps).

A suction pump is the type of hand water pump that we often envision when we think of the old days of pumping water on a homestead or farm.

In a suction pump, the pump cylinder and pump valves are above ground in the pump head. Repeated strokes of the pump handle gradually “sucks” water up the riser main and into the cylinder and out the spout.

Because of their mechanical limitations, the operational depth of a suction pump is limited to seven or eight meters.

Lift pumps are more commonly found in the developing world because the depth that water must be drawn from exceeds the limits of a suction pump.

Suction pumps are easier to work on than lift pumps because the pump cylinder and its associated parts are above ground and easily accessible.

But, most water-yielding aquifers are simply too deep for suction pumps, so lift pumps are more common.

Piston pumps have their pump cylinder below ground and below the level of the water table. Instead of “sucking” the water out of the well, they lift a column of water upwards through the riser main.

Each successive stroke of the pump handle causes the piston to displace more water up the riser until it flows out the spout.

Theoretically, there is no limit to the depth from which a piston pump can remove water.

In practice, however, the limit is determined by the power a human being can exert on the pump handle and the construction and materials of the pump cylinder, pump rod, piston valves, and piston seals.

Because the pump cylinder is below the water table, a long pump rod has to reach down to the pump cylinder, connecting it to the pump handle.

This complicates the maintenance process since the pump rod, the riser main, and the pump cylinder all have to be removed from the well, which can be hundreds of feet deep.

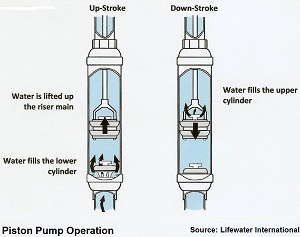

Up-Stroke

As you might expect, the piston assembly moves upward during the up-stroke.

During the upstroke the piston valve is closed.

Water that is in the upper cylinder is under positive pressure and is pushed upward into the riser main.

A negative pressure is created in the lower cylinder. This negative pressure causes the foot valve open and water is pulled into and fills the lower cylinder.

Down-Stroke

As the piston assembly moves downward, pressure increases in the lower cylinder and the foot valve closes.

Increasing pressure in the lower cylinder also pushes the piston valve open and water flows upward and fills the upper cylinder.

As the up-stroke is repeated, water is again pushed upward through the riser main.

This process is repeated over and over again as the pump handle is operated. Water moves from lower cylinder to upper cylinder and up the riser main.

The mechanisms that make this possible are the two one-way valves (piston valve and foot valve), the piston seals (which seal off upper cylinder from lower cylinder, and the pump rod which connects everything to the pump handle above ground.

Understanding this gives us insight into the important functional parts of the hand water pump and possible solutions to repairing pumps that malfunction.

(It should be remembered that a down-stroke of the pump handle causes an up-stroke of the piston assembly).

Deep Well, Direct Action, and VLOM Pumps

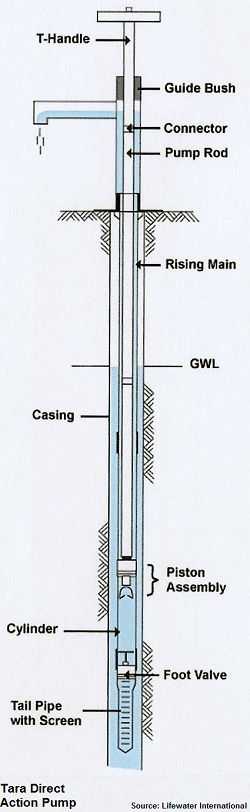

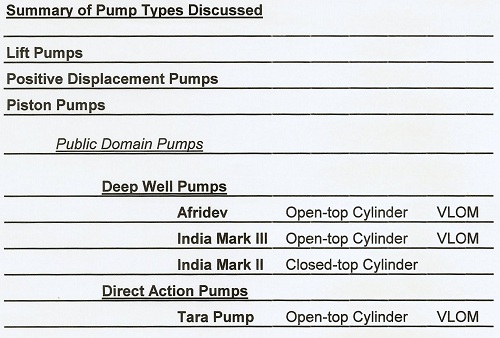

Piston pumps may further be categorized as “Deep Well Pumps” or“Direct Action Pumps”.

In our discussion of hand water pump repair, we will be focusing on

Deep Well Pumps (the Afridev, India Mark II and India Mark III, and Bush Pump) and

one Direct Action Pump; the Tara Pump.

Deep Well Pumps

As mentioned above, the pump cylinder on a deep well pump (or any lift pump) is placed below ground and below the water level.

The piston assembly containing the piston valve is connected to the pump handle by a pump rod (connecting rod).

The Afridev, India Mark II and India Mark III hand water pumps are common public domain deep well pumps and are found all over the world. The components of these hand water pumps are heavy duty cast or machined parts.

It is necessary that the components be strong and durable since they are expected to lift a heavy column of water hundreds of feet tall and to do this on a constant basis over a long period of time.

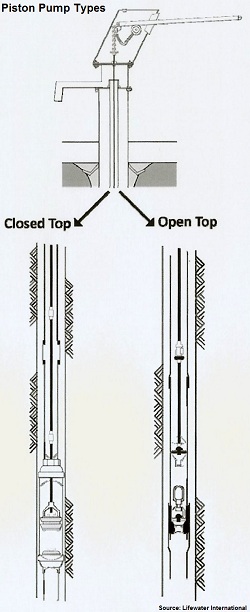

The India Mark II is a "closed-top" cylinder design. This design was the first and earliest design for deep well hand water pumps. When repair is required, the entire riser main, pump rod, and pump cylinder must be removed.

The advent of the “open-top”cylinder configuration, where the cylinder is the same diameter as the riser main, allows the pump rod, pump piston, and foot valve to be removed without removing the riser main. This makes maintenance considerably easier.

The Afridev and India Mark III pumps are of the open-top cylinder design. This design came later and enables the repair person to access the pump rod, the piston valve and the foot valve without pulling out hundreds of feet of riser main to get to them.

Since in an open-top cylinder, the pump cylinder is the same diameter as the riser main and is really just an extension of the riser main, just grabbing and pulling the pump rod pulls out the piston valve with it.

The Tara Pump is a "direct action pump". It is operated by a “T”-bar handle as opposed to a pump lever like the Afridev and India mark II and Mark III hand water pumps. The pump rod of the Tara pump is made of PVC pipe of a diameter slightly smaller than the PVC riser main. This allows water to be drawn from the well on the up-stroke as well as on the down-stroke.

On the up-stroke the piston assembly pushes water up the riser main just like in the other pumps. But, on the down-stroke, the PVC pump rod displaces water out of the riser main and again forces water up the riser main and out of the spout.

VLOM Pumps

Open-top cylinder pumps, like the Afridev, India Mark III, and Tara pumps are designed to be easier to maintain than closed-top cylinder pumps. They can be worked on easily by two or three people.

Engineering systems that are easier to maintain and operate embraces a design philosophy referred to as VLOM or Village Level Operation and Maintenance.

Hand water pumps that accommodate VLOM:

• Can be operated by a small child

• Can be installed by a team of two or three persons

• Are durable against corrosive groundwater

• Can have quickly worn parts easily purchased and replaced

Introducing public domain pumps was a first step toward making pumps and parts more accessible and affordable.

Designing open-top pumps took another step toward allowing remote villages to maintain pumps themselves and reduce the dependency of villages on governments and donor agencies.

Older pump designs and some current proprietary pumps are harder to work on, harder to find parts for, less resistant to corrosion, and unable to stand up to constant use.

Careful selection of a VLOM pump can solve these problems.

(The India Mark II is an older design. It is a closed-top pump. It was later updated to the India Mark III. A Mark II pump can be converted to a Mark III by replacing the water tank and the riser main.)

There must also be community involvement in any water project from beginning to end.

Sustainability requires that the community be fully involved in the planning, design, construction, and maintenance of their own water supply.

Hand pump maintenance and repair is just one aspect of an integrated and comprehensive community water program.

Return to "Hand Pump Repair" from "Hand Water Pumps"

Return "Home"

IMPROVE SUSTAINABILITY!

INCREASE YOUR IMPACT!

Alleviating Poverty/Advancing Prosperity

An Essential Guide for Helping the Poor

CLICK HERE to learn more about how YOU can create lasting change!

General Hand Pump Repair Guidelines

Afridev Hand Pumps and Deep Well Hand Pumps