The "SlapShot" Well Hand Pump is Easy to Build From Common Plumbing Parts and is Easy to Repair

The "SlapShot" Universal Well Hand Pump Cylinder

This easy-to-build pump cylinder was created by Hydromissions International in collaboration with missionary designers.

Their experiences in the field guided the concept and the development of this Village Level Operation and Maintenance (VLOM), direct-lift, piston well hand pump cylinder.

The pump cylinder is constructed of common plumbing parts that can be found in just about any hardware store or plumbing supply store.

If you or I were to go to Lowe’s or Home Depot, we could get the parts to build this well hand pump cylinder for about 45 dollars.

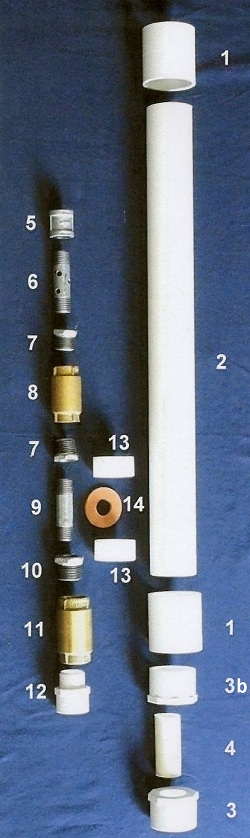

The “trick” parts of this pump and the secret to its successful operation are the two brass check valves (parts 8 and 11)with the springs removed and the ½” x 3” galvanized pipe nipple with holes drilled through the walls (part 6).

The check valves are one-way valves that allow water to flow in only one direction.

The foot valve (parts 11 and 12) is made of a 1” check valve; spring removed and arrow pointing upward. Water can flow up into the cylinder but not down out of the bottom of the cylinder. A foot valve seat is constructed of PVC fittings (parts 3, 3b, and 4).

The foot valve fits into the foot valve seat and is removable without having to remove the riser main or pump cylinder.

The valve in the upper cylinder is made of a ¾” check valve, spring removed, arrow pointing upward. Water can be pushed up into the riser main but not down into the lower cylinder.

Water taken into the pump cylinder by the foot valve travels up the inside of the piston assembly instead of around the outside of it, as it is in a conventional pump cylinder.

The holes in the pipe nipple allow water to exit the piston assembly and travel up the riser main.

Instead of "cup leathers" or a piston seal, there is a gasket that is used to separate the lower cylinder from the upper cylinder (part 14).

This gasket is sandwiched between two spacers (part 13). The function of the spacers is simply to hold and add strength to the gasket.

The effective sealing of the gasket may determine how deep this pump cylinder can be operated.

If the seal of the gasket yields under pressure at depth it may weaken the performance of the pump cylinder.

Adding more gaskets, sandwiched in between the spacers, will improve the seal and the performance of the SlapShot.

When built and used properly, this little pump cylinder will work for supplying water from a borehole well and it is cheap to build, easy to build, and easy to repair.

"SlapShot" Parts List (Lowe's SKU numbers provided)

1. (23902) 2” PVC coupling

2. (256099) 2” x 24” PVC pipe

3. (22909) 2” x 1” bushing

3b. (22909) 2” x 1” bushing (lip reamed out for foot valve seat)

4. 1” x 3” sch40 PVC pipe

5. (22300) ½” galv coupling

6. (24028) ½” x 3” galv pipe nipple

7. (21860) ¾” x ½” galv bushing

8. (61252) ¾” brass check valve (spring removed)

9. (24028) ½” x 3” galv pipe nipple (1/4” holes drilled for lift flow)

10. (21870) 1” x ½” galv bushing

11. (187372) 1” brass check valve (spring removed)

12. (23858) 1” pvc adaptor

13. 2” O.D. x 7/8” I.D. x 1” thick spacer (DIY part or Hydromissions part #SS-02 “Slapshot gasket & spacer set)

14. 2” O.D. x 7/8” I.D. x ¼” thick leather gasket (DIY part or Hydromissions part #SS-02 “Slapshot gasket & spacer set)

Hydromissions International's instructions for Slapshot Well Hand Pump construction can be accessed here:

"Hydromissions "SlapShot" Pump Construction"

Return to "Hand Pumps" from "Well Hand Pump"

Return "Home"