Biosand Filters Have Been Designed and Refined to Achieve Up To 99% Removal of Disease-Causing Pathogens If Built and Operated Properly

Biosand filters can achieve up to 99% removal of disease-causing pathogens if built and operated properly.

Note: The content on this page has been adapted from publications of Centre for Affordable Water and Sanitation Technology (CAWST).

The following sections describe the proper use of the biosand filter to ensure the highest level of treatment efficiency.

Water Source

This type of filter can be used with any water source such as rainwater, deep groundwater, shallow groundwater, rivers, lakes or other surface water.

When filtering water in a biosand filter, you want to start with the cleanest possible water you can find. The filter may not be able to remove 100% of the pathogens and turbidity.

If the source water is very contaminated, the filtered water may still have some contaminants. So, to get the cleanest possible water from the biosand filter, start with the cleanest water you can find.

Over time, the biolayer becomes adapted to a water source that contains a certain amount of contamination. If source water with a different level and type of contamination is used, the biolayer may not be able to consume all of the pathogens.

It may take the biolayer several days to adapt to the new source water, level of contamination, and nutrients.

The turbidity of the source water is also a key factor in the operation of the filter. Higher turbidity levels will plug the filtration sand layer more quickly. As such, maintenance will be required more often to ensure a convenient flow rate for the user.

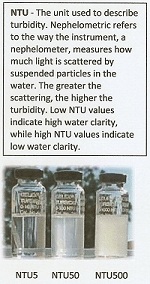

It is recommended to use a sedimentation method if the source water turbidity is greater than 50 NTU.

A simple test to measure the turbidity is to use a 2 liter clear plastic bottle filled with the source water. Place this on top of some large black print.

If you can see the large black print looking down through the top of the bottle, the water probably has a turbidity of less than 50 NTU.

The Biolayer

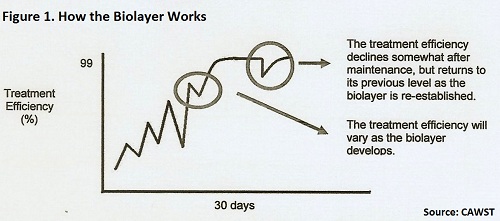

The biolayer is the key component of the filter that removes pathogens. Without it, the filter removes about 30-70% of the pathogens through mechanical trapping and adsorption. The ideal biolayer will increase the treatment efficiency up to 99% removal of pathogens.

It may take up to 30 days for the biolayer to fully form. During that time, both the removal efficiency and the oxygen demand will increase as the biolayer grows.

The biolayer is NOT visible - it is NOT a green slimy coating on top of the sand. The filtration sand may turn a darker color but this is due to the suspended solids that have become trapped.

The water from the filter can be used during the first few weeks while the biolayer is being established, but disinfection, as always, is recommended during this time.

Figure 1 illustrates how the biolayer develops over time. The process may vary as some filters require a shorter or longer period of time to establish the biolayer depending on the amount and source of water being used.

Filter Loading Rate

Biosand filters have been designed to allow for a filter loading rate (flow rate per square meter of sand surface area) which is specific for each biosand filter design and has proven to be effective in laboratory and field tests.

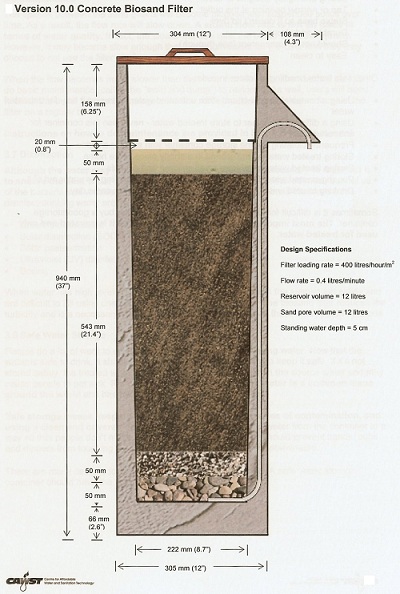

There is a recommended filter loading rate for each filter design. For the concrete Version 10 biosand filter developed by CAWST, it has been determined to be not more than 400 liters/hour/square meter.

In the Version 10 filter, the volume of the water reservoir is equal to the pore space volume of the sand layer. This is an important design characteristic of an effective biosand filter.

After the pause period, a volume of water equal to the reservoir volume will be filtered and available for drinking.

For proper filter operation and maximum filtering, the volume of the reservoir and the volume of the pore space in the sand layer must be equal.

Pause Period

The filter is most effective and efficient when operated intermittently and consistently. The pause period should be a minimum of 1 hour after the water has stopped flowing up to a maximum of 48 hours.

The pause period is important because it allows time for the microorganisms in the biolayer to consume the pathogens in the water. As the pathogens are consumed, the flow rate through the filter may be restored.

If the pause period is extended for too long, the microorganisms will eventually consume all of the nutrients and pathogens and then eventually die off. This will reduce the removal efficiency of the filter when it is used again.

Standing Water Layer

Correct installation and operation of the filter requires a standing water depth of approximately 5 cm (2'') above the sand during the pause period.

The standing water depth can be 4-6 cm, but ideally it should be at 5 cm (2"). A water depth of greater than 5 cm (2'') results in lower oxygen diffusion and consequently a thinner biolayer.

A high water level can be caused by a blocked outlet tube, an insufficient amount of sand installed in the filter or the sand settling in the first few weeks of use.

A water depth less than 5 cm (2'') may evaporate quickly in hot climates and cause the biolayer to dry out. A low water level may be caused by too much sand being put into the filter during installation.

Return to "Biosand Filters" from "Biosand Filter Operation"

Return "Home"